Autonomous logistics: why blockchain suddenly matters

From buzzwords to moving boxes in the real world

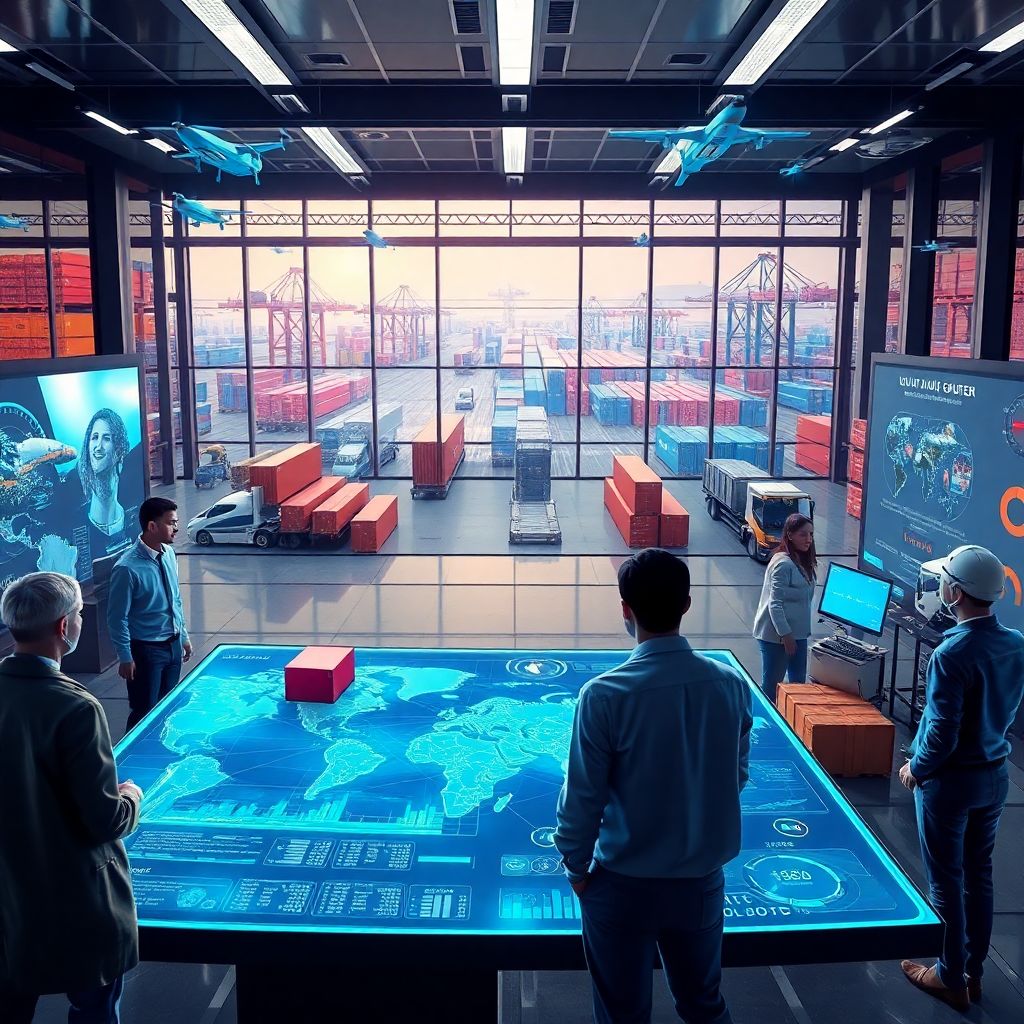

Autonomous logistics sounds futuristic, but it’s really about one simple thing: getting goods from A to B with minimal human micromanagement. Drones, AGVs, robot forklifts and IoT sensors already do a lot of the physical work. The real bottleneck is digital: who owns the data, who can see it, and who you can trust when there’s a dispute. That’s exactly where blockchain steps in—not as a magic wand, but as a shared “source of truth” that every partner in the supply chain can rely on without blind faith in a single central platform or intermediary.

What actually changes with blockchain in logistics

Instead of each company running its own isolated TMS or WMS and emailing Excel files, blockchain creates a shared ledger where shipments, handovers and quality checks are recorded as immutable events. Think of it as an audit trail that no one can quietly “edit” after the fact. On top of this ledger you can plug in blockchain enabled supply chain management software that syncs with existing ERPs. It doesn’t replace every system you have, but coordinates them like an air traffic controller orchestrating many different planes using one consistent radar picture.

Real cases: where it already works

Food and pharma traceability that actually holds up in audits

One of the earliest real wins came in food and pharmaceuticals, where regulators demand traceability down to batch and even pallet level. Several blockchain logistics companies for supply chain optimization co‑built networks where every movement—from farm or factory to retailer—is logged with temperature, location and custody data. When a recall hits, they can narrow down the affected batches in minutes instead of days. An expert tip from these projects: don’t start with “track everything”. Start with two or three high‑risk product families and a limited corridor, then scale once internal teams stop fighting the new workflows.

Ports, containers and freight settlements

Container logistics is a nightmare of overlapping documents, brokers and forwarders. In pilot projects at major ports, carriers, customs and terminal operators used blockchain supply chain solutions for logistics to push key events—vessel arrival, container release, customs clearance—into a shared ledger. Smart contracts then triggered automatic release messages once all conditions were met, cutting dwell time and manual phone calls. A shipping CIO involved in one such project noted that the technical stack was the easy bit; the hard work was in getting legal teams comfortable that the digital records would stand in court as evidence of who did what and when.

“Invisible” but powerful: invoice and dispute automation

Another real but less visible case is automated freight invoicing. Some autonomous logistics platforms using blockchain now let carriers and shippers agree lane prices on‑chain. When IoT confirms pickup, transit and delivery on time, the smart contract self‑issues an invoice and initiates payment. If GPS data or temperature logs show a deviation, a dispute is automatically flagged with all evidence attached. According to consultants running these programs, the biggest ROI doesn’t come from cutting people; it comes from shrinking Days Sales Outstanding and slashing the number of ugly month‑end reconciliation calls between finance teams on both sides.

Non‑obvious solutions that practitioners actually use

Using blockchain as a “data firewall” between frenemies

Supply chains are full of “coopetition”: partners who work together but also compete. A non‑obvious move is using the ledger as a controlled data layer between these frenemies. For instance, a retailer and 3PL can write shipment status, handover times and damage reports on‑chain, while keeping sensitive volumes and margin data off‑chain. Access policies define which attributes each party can read. Experts stress that this “minimum necessary data” approach makes adoption feasible: you share verifiable facts without exposing pricing secrets, which calms sales departments that usually block radical transparency projects out of fear of losing negotiation leverage.

Encoding SLAs as smart contracts instead of static PDFs

Classic SLAs live in PDFs nobody reads after signing. With smart contracts for logistics and supply chain automation, you embed SLA logic directly into code: if on‑time delivery drops below 97% for two weeks, an automatic rebate kicks in; if temperature exceeds limits, an incident workflow is triggered. Practitioners warn against putting full legal text on‑chain; instead, the contract references an off‑chain legal document and only codifies clear, measurable KPIs. The trick is to keep the on‑chain logic simple enough that operations teams can simulate scenarios and understand consequences without needing a full legal review every time a parameter changes.

Alternative methods: when blockchain is not the only answer

Centralized control towers and EDI still have a place

Before jumping onto blockchain, many companies already use control towers, EDI hubs and visibility platforms. These alternative methods work well when there is a strong lead company and everyone else accepts its rules. A centralized cloud provider can aggregate tracking data, run optimization algorithms and expose APIs. The trade‑off is trust and lock‑in: that provider becomes a single point of failure and a potential gatekeeper of meta‑data like lane performance. Experts usually recommend starting by stress‑testing your current control tower: if partners constantly question the data or argue over “who changed what”, you’ve hit the ceiling of centralization and should consider a shared ledger.

Federated data spaces and API ecosystems

Another alternative to blockchain supply chain solutions for logistics is building federated data spaces, where each company keeps data locally but adheres to common interoperability standards. Access is controlled through API gateways, and events are streamed using technologies like Kafka. This can be easier to govern inside one region or corporate group. However, as the network grows and new players come and go, versioning, auditability and long‑term data integrity become serious headaches. Several experts see blockchain as a natural next layer for these ecosystems once the number of bilateral API contracts becomes impossible to manage without a shared, tamper‑evident event backbone.

Pro tips and lifehacks for professionals

How to avoid the classic blockchain-in-logistics pitfalls

1. Start with a painful dispute, not a pretty dashboard. Choose use cases where lack of trust or constant discrepancies already cost you money; this maximizes buy‑in.

2. Design data models with auditors at the table. Compliance and legal should help define which events must be immutable so you avoid retrofitting governance later.

3. Integrate, don’t rip and replace. The most successful projects wrap existing WMS/TMS with adapters, turning them into nodes in a broader network instead of forcing a big‑bang migration.

4. Separate business rules from code. Keep thresholds and SLA parameters configurable so operations can tweak them without redeploying smart contracts each time.

Organizational hacks from teams that shipped real networks

Seasoned architects say that the tech stack for autonomous logistics platforms using blockchain is rarely the bottleneck; governance is. One hack is to create a neutral “network operator” entity that is not a direct competitor to any participant—sometimes a joint venture, sometimes an industry association. That body owns the reference implementation and onboarding process. Another tip is to run pre‑competitive pilots: competitors collaborate on common tracking standards, while keeping pricing and capacity management proprietary. This lowers the political temperature and lets people judge the system on latency, resilience and data quality rather than on who “controls” it.

Expert recommendations and strategic outlook

How to evaluate if your supply chain is ready

Experts in blockchain logistics companies for supply chain optimization often start with a brutally honest assessment: if you don’t have basic process discipline or digitized events, blockchain won’t magically fix that. You need reasonably clean master data, standardized milestones and at least partial IoT coverage. Once that’s in place, blockchain enabled supply chain management software can become the coordination fabric across partners. The forward‑looking play is to pair it with AI: use the ledger as a trustworthy data lake, then run predictive ETAs, capacity forecasts and risk scoring models on top, knowing that your algorithms aren’t consuming quietly edited or selectively shared data.

Final thought: autonomy is more about agreements than robots

Autonomous logistics is not just robots driving forklifts; it’s about codifying inter‑company agreements so goods can flow with minimal email, phone and spreadsheet friction. Blockchain doesn’t replace the complexity of global trade, but it does change where you store and verify the truth about what happened. If you focus first on thorny cross‑company pain points, involve legal and finance early, and keep on‑chain logic lean and auditable, you can move beyond blockchain hype and build supply networks that are both more autonomous and more accountable—without betting the farm on unproven, all‑or‑nothing transformations.